System Maintenance: 7 Ultimate Secrets for Peak Performance

Keeping your systems running smoothly isn’t just about fixing problems—it’s about preventing them. System maintenance is the silent hero behind every reliable machine, software, or network. Whether you’re managing a server, a car, or a smart home, regular upkeep ensures longevity, efficiency, and peace of mind.

What Is System Maintenance and Why It Matters

System maintenance refers to the routine activities performed to keep systems—be they mechanical, software-based, or networked—functioning efficiently and reliably. It’s not just about reacting to failures; it’s about proactive care to prevent downtime, reduce costs, and extend the lifespan of critical assets.

Defining System Maintenance in Modern Contexts

In today’s digital and industrial landscape, system maintenance spans a wide range of applications—from maintaining operating systems on computers to servicing HVAC units in commercial buildings. At its core, it involves inspection, testing, servicing, repair, and replacement of components to ensure optimal performance.

- Applies to both hardware and software systems

- Includes scheduled checks and emergency interventions

- Crucial for safety, compliance, and operational continuity

The High Cost of Neglecting System Maintenance

Ignoring system maintenance can lead to catastrophic failures. A study by the International Society of Automation (ISA) found that unplanned downtime costs industrial manufacturers an estimated $50 billion annually. In IT, poor server maintenance can result in data breaches, lost productivity, and reputational damage.

“An ounce of prevention is worth a pound of cure.” — Benjamin Franklin

This timeless quote perfectly encapsulates the value of system maintenance. The small investment in regular upkeep pales in comparison to the financial and operational toll of system failure.

The 4 Core Types of System Maintenance

Understanding the different types of system maintenance helps organizations choose the right strategy for their needs. Each type serves a unique purpose and is suited to specific environments and risk profiles.

Corrective Maintenance: Fixing What’s Broken

Corrective maintenance, also known as reactive maintenance, involves repairing or replacing equipment after a failure has occurred. While it may seem inefficient, it’s sometimes the most practical approach for non-critical systems.

- Used when failure doesn’t significantly impact operations

- Lower upfront costs but higher long-term risks

- Common in small businesses with limited resources

For example, replacing a printer after it stops working is a form of corrective maintenance. However, in mission-critical environments like hospitals or data centers, this approach is too risky.

Preventive Maintenance: Staying Ahead of Failure

Preventive maintenance is a scheduled approach where systems are serviced at regular intervals to prevent unexpected breakdowns. This is one of the most widely adopted strategies across industries.

- Includes tasks like lubricating machinery, updating software, or cleaning filters

- Reduces the likelihood of sudden failures

- Improves system reliability and lifespan

According to Maintenance.org, organizations that implement preventive maintenance programs report up to 12% lower maintenance costs and 17% higher productivity.

Predictive Maintenance: Using Data to Forecast Issues

Predictive maintenance takes preventive strategies a step further by using real-time data and analytics to predict when a system is likely to fail. Sensors, machine learning, and IoT devices play a crucial role here.

- Monitors vibration, temperature, pressure, and other indicators

- Enables maintenance only when needed, reducing unnecessary interventions

- Widely used in aviation, manufacturing, and energy sectors

For instance, jet engines are equipped with sensors that transmit performance data to ground stations. Engineers can detect anomalies before they become critical, scheduling maintenance during routine layovers.

Perfective Maintenance: Enhancing System Performance

Perfective maintenance focuses on improving system functionality and user experience, even when no failure has occurred. This is common in software development and IT infrastructure.

- Involves optimizing code, upgrading interfaces, or enhancing security features

- Driven by user feedback and evolving requirements

- Ensures systems remain relevant and efficient over time

A real-world example is a mobile banking app receiving regular updates to improve load times and add biometric login options. These changes aren’t fixes—they’re enhancements that keep the system competitive.

System Maintenance in IT: Servers, Software, and Security

In the digital world, system maintenance is non-negotiable. From corporate servers to personal laptops, every device requires ongoing care to function securely and efficiently.

Server Maintenance: The Backbone of Digital Operations

Servers host critical applications, databases, and websites. Regular server maintenance ensures uptime, performance, and data integrity.

- Tasks include updating operating systems, monitoring disk space, and checking logs

- Backups must be tested regularly to ensure recoverability

- Hardware components like fans and power supplies need inspection

According to Red Hat, poorly maintained servers are 3.5 times more likely to experience downtime. A single hour of server outage can cost large enterprises over $100,000.

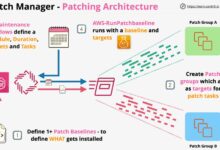

Software Updates and Patch Management

Software doesn’t degrade like hardware, but it becomes vulnerable over time. Patch management is a key aspect of system maintenance in IT.

- Security patches fix vulnerabilities exploited by hackers

- Feature updates improve functionality and compatibility

- Automated tools like WSUS or SCCM streamline the process

The 2017 WannaCry ransomware attack exploited a known Windows vulnerability that had a patch available—but many organizations hadn’t applied it. This highlights the deadly consequences of neglecting software maintenance.

Cybersecurity and System Maintenance

Maintenance isn’t just about performance—it’s a cornerstone of cybersecurity. Regular audits, firewall updates, and malware scans are essential.

- Firewalls and antivirus software must be updated daily

- User access controls should be reviewed periodically

- Security logs need to be analyzed for suspicious activity

The National Institute of Standards and Technology (NIST) recommends a continuous monitoring approach, where system maintenance and security go hand-in-hand. You can learn more at NIST.gov.

Mechanical and Industrial System Maintenance

From factory assembly lines to HVAC systems, mechanical equipment relies heavily on structured maintenance programs to avoid costly breakdowns.

Maintenance in Manufacturing: Maximizing Uptime

In manufacturing, unplanned downtime can halt production and delay shipments. System maintenance ensures machines operate at peak efficiency.

- Regular calibration of robotic arms and CNC machines

- Lubrication of conveyor belts and gears

- Inspection of electrical connections and sensors

A case study from General Electric showed that predictive maintenance reduced machine downtime by 35% and extended equipment life by 20%.

HVAC System Maintenance for Energy Efficiency

Heating, ventilation, and air conditioning (HVAC) systems consume up to 40% of a building’s energy. Proper maintenance can significantly reduce energy costs.

- Replace air filters every 1–3 months

- Clean coils and drains to prevent mold and blockages

- Check refrigerant levels and thermostat accuracy

The U.S. Department of Energy states that regular HVAC maintenance can improve efficiency by 15–20%. This not only saves money but also reduces environmental impact.

Automotive System Maintenance: Beyond Oil Changes

Modern vehicles are complex systems with mechanical, electrical, and software components. Maintenance goes far beyond oil changes.

- Brake inspections, tire rotations, and fluid checks

- Software updates for infotainment and driver-assistance systems

- Diagnostic scans using OBD-II tools

Ignoring maintenance can void warranties and lead to expensive repairs. The American Automobile Association (AAA) recommends a full vehicle inspection at least twice a year.

System Maintenance in Smart Homes and IoT Devices

As homes become smarter, the need for system maintenance extends to connected devices like thermostats, cameras, and voice assistants.

Updating Firmware on Smart Devices

Firmware is the software embedded in hardware. Keeping it updated is critical for security and performance.

- Smart locks, cameras, and routers receive regular firmware updates

- Updates often fix bugs and close security loopholes

- Some devices update automatically; others require manual intervention

For example, Ring doorbells have had multiple firmware updates to improve video quality and prevent hacking attempts.

Network Health and Wi-Fi Optimization

A smart home is only as good as its network. System maintenance includes ensuring strong, secure Wi-Fi coverage.

- Restart routers periodically to clear memory leaks

- Change default passwords and enable WPA3 encryption

- Use mesh networks to eliminate dead zones

Google’s Nest Wi-Fi system includes built-in maintenance features like automatic channel selection and security alerts.

Managing Device Compatibility and Integration

As new devices are added, system maintenance ensures they work seamlessly with existing ones.

- Check for compatibility with platforms like Apple HomeKit or Google Home

- Update hub software (e.g., Samsung SmartThings)

- Remove unused devices to reduce network clutter

Without proper integration, smart homes can become fragmented and frustrating to use.

Best Practices for Effective System Maintenance

Whether you’re managing a single device or an entire enterprise network, following best practices ensures your system maintenance efforts are effective and sustainable.

Create a Comprehensive Maintenance Schedule

A well-structured schedule is the foundation of any maintenance program. It ensures tasks are performed consistently and nothing is overlooked.

- Use digital calendars or CMMS (Computerized Maintenance Management Systems)

- Assign responsibilities to specific team members

- Include both daily checks and annual overhauls

Tools like UpKeep or Fiix help organizations automate scheduling and track completion rates.

Document Every Maintenance Activity

Documentation provides a historical record of what was done, when, and by whom. This is invaluable for audits, troubleshooting, and training.

- Log repairs, replacements, and inspections

- Attach photos, invoices, and technician notes

- Store records in a centralized, searchable database

In regulated industries like healthcare or aviation, maintenance logs are legally required.

Train Staff and Promote a Maintenance Culture

Even the best systems fail without knowledgeable personnel. Training ensures everyone understands the importance of system maintenance.

- Conduct regular workshops on new tools and procedures

- Encourage employees to report issues early

- Recognize and reward proactive maintenance behavior

Companies with strong maintenance cultures report 30% fewer incidents and higher employee engagement.

Common Challenges in System Maintenance and How to Overcome Them

Despite its importance, system maintenance often faces obstacles that can undermine its effectiveness.

Resource Constraints: Time, Budget, and Personnel

Many organizations struggle to allocate sufficient resources to maintenance. Budgets are tight, and staff are stretched thin.

- Solution: Prioritize critical systems using risk assessment matrices

- Outsource non-core maintenance tasks to specialists

- Invest in automation to reduce labor requirements

For example, using automated patch management software reduces the need for manual IT intervention.

Resistance to Change and Lack of Awareness

Some teams resist new maintenance protocols, especially if they disrupt workflows.

- Solution: Communicate the benefits clearly with real-world examples

- Involve staff in planning and decision-making

- Start with small, high-impact changes to build momentum

Change management principles from sources like Prosci.com can help ease transitions.

Managing Legacy Systems

Older systems may lack support, spare parts, or compatibility with modern tools.

- Solution: Develop a phased migration plan to newer platforms

- Maintain detailed documentation for legacy systems

- Partner with vendors who specialize in legacy support

While costly, upgrading legacy systems often pays off in reduced downtime and improved security.

The Future of System Maintenance: AI, Automation, and Predictive Analytics

Technology is transforming how we approach system maintenance. What was once manual and reactive is becoming intelligent and proactive.

Artificial Intelligence in Predictive Maintenance

AI algorithms analyze vast amounts of data to detect patterns and predict failures before they occur.

- Machine learning models learn from historical failure data

- Natural language processing can analyze maintenance logs for insights

- AI-powered chatbots assist technicians with troubleshooting

IBM’s Watson AIOps uses AI to detect anomalies in IT systems and recommend corrective actions in real time.

Robotic Process Automation (RPA) for Routine Tasks

RPA bots can perform repetitive maintenance tasks like log cleanup, user provisioning, and report generation.

- Reduces human error and frees up staff for complex work

- Can run 24/7 without fatigue

- Integrates with existing systems via APIs

UiPath and Automation Anywhere offer RPA solutions tailored for IT and industrial maintenance.

The Rise of Self-Healing Systems

Next-generation systems are being designed to detect and fix issues autonomously.

- Cloud platforms like AWS automatically restart failed instances

- Self-healing networks reroute traffic around outages

- Firmware updates can be triggered by performance degradation

While still evolving, self-healing systems represent the ultimate goal of system maintenance: zero downtime through automation.

What is the most important type of system maintenance?

Preventive maintenance is often considered the most important because it stops problems before they occur. However, the best approach combines preventive, predictive, and corrective strategies based on the system’s criticality and usage.

How often should system maintenance be performed?

Frequency depends on the system. Software updates may be daily, while HVAC servicing is typically biannual. Critical systems like servers or medical equipment may require weekly or even real-time monitoring.

Can system maintenance be fully automated?

While many tasks can be automated—like software updates or sensor monitoring—human oversight remains essential for complex diagnostics, decision-making, and handling unexpected failures.

What are the consequences of poor system maintenance?

Poor maintenance leads to increased downtime, higher repair costs, safety hazards, data breaches, and reduced system lifespan. In extreme cases, it can result in regulatory fines or loss of life.

Is system maintenance necessary for personal devices?

Absolutely. Regular updates, disk cleanup, and security scans on personal computers and smartphones prevent slowdowns, crashes, and cyberattacks. Just like cars, personal devices need routine care to perform well over time.

System maintenance is far more than a technical checklist—it’s a strategic discipline that safeguards performance, security, and reliability across every domain. From the servers powering global businesses to the smart thermostats in our homes, consistent upkeep ensures systems deliver value over their entire lifecycle. By embracing preventive strategies, leveraging modern tools, and planning for the future, individuals and organizations can avoid costly failures and operate with confidence. The key is not to wait for breakdowns but to build a culture of continuous care. In a world where systems are increasingly complex and interconnected, proactive system maintenance isn’t optional—it’s essential.

Further Reading: